FAQs

Bradford's Knowledge Centre is the place for frequently asked questions about our products, installation, safety, the science of insulation and other topics.

These are some of the most commonly asked questions regarding our products. If you have a query which is not covered, please contact us so we can assist you.

General

-

What R-Value do I require in my home to meet NZ minimum requirement for Insulation?

The New Zealand Building Code requires all new home builds and existing home renovations/additions to meet the following minimum insulation requirements:

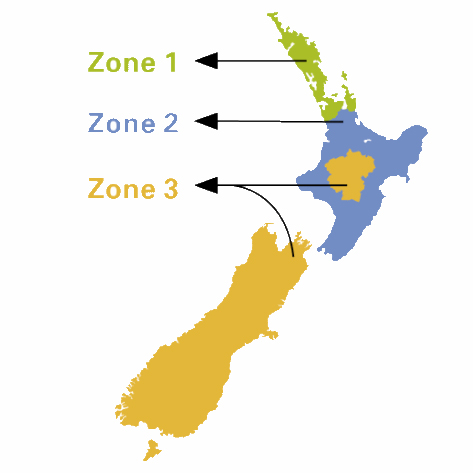

Zone 1 & 2 Wall – R1.9 Ceiling – R2.9 Floor – R1.3 Zone 3 Wall – R2.0 Ceiling – R3.3 Floor – R1.3 NZ Climate Zones are as follows:

These minimum R-Values are also relevant under the new Residential Tenancies Act (RTA) amendment, which requires all rental properties to have underfloor and ceiling insulation by 2019 (where possible). For more information visit the MBIE website.

-

Can Bradford install insulation?

Bradford has been supplying the New Zealand market with Glasswool insulation for over 25 years and during this time has built a loyal installer base across the country to ensure you can get Bradford insulation installed into your new or existing home by a professional installer. To find your local Bradford Insulation installer please contact us.

-

How are glasswool segments installed?

Glasswool segments come in standard widths and lengths that match standard joist spaces. With ceiling insulation the segments are usually brought into an existing ceiling access and fit snugly between ceiling joists to achieve maximum thermal insulation.

-

Installation of Gold segments requires careful attention to sealing gaps between insulation and studs or joists. Why is this so important?

Even if only 5% of an area of wall or ceiling is left uninsulated then up to 50% of the potential benefits may be lost. Similarly holes, tears or joins in reflective insulation should be taped.

-

What is the density of residential insulation products?

The density of glasswool products used in residential applications varies depending on the use of the product. Ceiling segments are normally in the range of 8 – 10kg/m3 whereas wall segments need to be stiff so as not to slump in the wall cavity and these products are typically 12kg/m3 or more. Acoustic insulation products are typically in the range of 25 – 30kg/m3.

-

What is the difference between glasswool & rockwool?

Glasswool and rockwool are similar products that perform similar functions. Glasswool takes molten glass (made from around 80% recycled glass) and put this through a fiberising process to create a mat of varying thicknesses and densities. This mat has millions of air pockets created and this provides an effective insulation against the transfer of heat. Rockwool is made in a similar way from molten volcanic rock (basalt) rather than glass. The main differences between glasswool and rockwool from a performance perspective is that rockwool cannot be made a low densities like glasswool can. The minimum density for rockwool is around 30kg/m3. However, rockwool has the advantage of being able to be used at much higher operating temperatures – up to 850°C compared to 350°C for glasswool. Mineral wool is a term that describes both glasswool and rockwool.

-

How can I get the best thermal performance out of a 90mm stud wall?

Bradford recommends using Bradford Gold R2.8 wall segments for optimum thermal performance. Bradford suggests increasing your studs to 140mm from 90mm to allow for more insulation. Bradford Gold 140mm wall segments are available in R4.0 R-Value (Bradford Gold High Performance) and R3.5 R-Value (Bradford Gold).

-

Will insulation fitted into timber studs eliminate noise transfer between rooms?

Glasswool and rockwool assist in muffling noise, to eliminate noise transfer between rooms requires attention also to the appropriate layers of plasterboard and close attention to eliminating flanking noise. It is the overall system, not just the insulation that should be considered.

-

Will Acoustic Gold insulation installed in the cavity of an external wall eliminate outside noise from entering a house?

Acoustic Gold will absorb much of the noise entering a home from outside, but noise tends to find a “path of least resistance” and so elements like windows, gaps around doors and windows and even the construction of the doors will have an effect. Double glazing, solid core doors and door and window seals will all play a role. Increasing the thickness of plasterboard will also assist in managing the entry of external noise.

-

What are the best options for reducing noise being transferred from the first floor to ground floor of a house?

Two types of noise need to be considered here: airborne noise and impact noise. Airborne noise is reduced by increased mass of the system, such as installing Bradford Acoustic Gold R2.2 and replacing standard plasterboard with 2 layers of 16mm fire rated premium plasterboard fixed to the ceiling joists. Impact noise, such as from footsteps, is best reduced by the use of carpet and underlay.

-

Can insulation reduce condensation and mould growth on ceilings of a bedroom?

When correctly installed, insulation can assist in reducing condensation and mould problems by keeping internal surfaces warmer. Other factors that should also be considered are ventilation, low room temperatures and high humidity levels in the house. For more information on ventilation, please visit www.edmondsventilation.co.nz.

-

What can I do to reduce the risk of mould and water damage due to internal condensation?

There are many Bradford products that will help reduce the risk of mould and water damage in your home. The Bradford Enviroseal™ ProctorWrap™ HTX of vapour permeable membranes are highly permeable, yet also water tight. These products are designed to allow moisture to pass through them whilst preventing the entry of wind driven rain and dust from the outside environment both during and after construction. The Edmonds range of home ventilation products all work hand-in-hand with insulation, to create a more comfortable and energy efficient home. It is also important to eliminate recessed light fittings. Duct kitchen and bathroom exhaust fans should direct air outside.

-

R-Value of Thermoseal Facing Foil: Does the orientation and position of the reflective foil influence the R-value?

Yes, the R-value of reflective foil depends on the orientation of the foil, ie. horizontal or vertical and the direction of heat flow. Air spaces of 20mm minimum are required for reflective foil to be effective. Foil laid over a ceiling lining with insulation on top has no R-value, it acts only as a vapour barrier.

-

How do I insulate a Cathedral Ceiling?

It is very difficult (and sometimes impossible) to insulate cathedral ceilings after they have been built.

If the cathedral ceiling has exposed rafters then it’s virtually impossible to insulate without a major structural change to the roof. If the rafters are not exposed (i.e. they sit behind the ceiling lining), then a cathedral ceiling can be insulated with Bradford segments by removing either the roofing material or the ceiling lining but obviously this is a difficult and expensive process and would only be cost effective if a re-roof was being done for other reasons or if other alterations were taking place that required the ceiling lining to be replaced.

-

How has this insulation been tested to prove it solves energy efficiency problems?

Insulation in New Zealand must be tested as per the standard AS/NZS4859.1. There are different tests for different types of insulation. For the most popular insulation which is glasswool, which we market as Bradford Gold Segments, we test this so that the claimed thermal performance (R-value) of the product is the same as what we claim on the packaging. This is done in the factory as part of our quality control process and through the BRANZ appraisal process.

Having established that the thermal performance is accurate, we then use this in modelling to estimate how much energy a home will need to achieve a comfort level of between 22 – 26°C. Because a well insulated house requires less energy to achieve this comfort range this helps improve the energy efficiency of the home.

Health and Safety

-

Is Bradford Insulation safe for my family?

Bradford has been manufacturing insulation in Australia since 1934. We started with Slagwool, then went to Rockwool and we have been making Glasswool now for almost 50 years. Glasswool insulation has been comprehensively researched over more than 30 years and the World Health Organisation has concluded that glasswool does not pose any long term health hazard.

-

How is glasswool different from fibreglass insulation?

There is no difference. In the USA glasswool is still referred to as fiberglass but in Europe, Australia and New Zealand the term changed to Glasswool in the 1980’s.

-

Has fibreglass insulation been banned in the USA?

No. This rumour has been around for many years and was started by manufacturers of alternative insulation products as part of a negative marketing campaign. In fact, glasswool is the most common insulation product used in residential homes in the USA and worldwide.

-

Are glasswool and rockwool a health hazard?

Glasswool and rockwool are manufactured using the latest bio-soluble formulation and are assessed as non-hazardous. Bradford Insulation's rockwool and glasswool have been classified as Category 3 by IARC (International Agency into Research on Cancer) and are not classifiable as carcinogens to humans. Any suggestion to the contrary is incorrect. Bradford Gold and Bradford Acoustic Gold insulation have been recognised as safe for asthma and allergy sufferers by the Asthma and Respiratory Foundation New Zealand’s 'Sensitive Choice' program. Please see Product Health & Safety for more information.

-

Will I get itchy installing glasswool?

The great benefit of creating an insulation product out of glass fibers is that they are inert and strong to provide lifetime performance. However when the fibers are cut to shape the factory some sharper edges and a small amount of loose dust is generated. These may cause minor temporary irritation for some people during installation. This is a mechanical irritation not chemical – it can be relieved by washing with soap and water or avoided by installing with dust mask and long sleeve shirt as recommended by Bradford.

After installation there is no risk of irritation if left undisturbed. In general roof spaces and building sites are dusty environments and Bradford recommends protective equipment be worn when working with any material in these spaces.

Residential

-

Can ceiling segments be used in walls?

Ceiling segments are too thick and not rigid enough to be fitted into studs without compression (and subsequent R-value). Wall segments have a water repellent added whereas ceiling segments don't.

-

Is Glasswool insulation compatible with down lights?

The NZ domestic downlight standard (AS/NZS 60598.2.2) coupled with Bradford Gold ceiling insulation means that you can now have the attractive lighting you want, without compromising on heat loss by abutting insulation directly to downlights that are compliant to AS/NZ S60598.2.2. Bradford Gold has been through rigorous testing to warrant this and passes Fire Hazard Test AS/NZ 60695.11.5.

-

Can insulation be installed directly on top of my plasterboard?

Yes, it can. Although, there are some loose fill products that will exceed the weight recommendations by plasterboard manufacturers. All of Bradford’s glasswool products are safe to install on plasterboard ceilings.

-

Is stringing of timber studs necessary when installing wall segments? (Residential)

Yes, unless wall wraps are used on the outside of the frame. This helps prevent the wall segment from falling and touching the external cladding.

Commercial

-

R-Value of Metal Deck Roof Structures: What factors influence the R-value of a metal deck roof?

The installed R-value of the glasswool and foil are dependant on the thickness of insulation and the degree of compression of the blanket under the metal deck. A still airspace created by a ceiling increases the R-value of the foil component particularly for summer conditions where heat flows downward.

-

R-Value of Thermoseal Facing Foil: Does the orientation and position of the reflective foil influence the R-value?

Yes, the R-value of reflective foil depends on the orientation of the foil, ie. horizontal or vertical and the direction of heat flow. Air spaces of 20mm minimum are required for reflective foil to be effective. Contact Bradford for details as the system R-value when reflective membranes are used are dependent on many variables.

-

R-Value of Metal Deck Roof Structures: What factors influence the R-value of a metal deck roof?

The installed R-value of the glasswool and foil are dependent on the thickness of insulation and the degree of compression of the blanket under the metal deck. Compression should be kept to a minimum and the use of spacers can achieve this where safety mesh is used. The insulation value attributable to the reflective foil facing is dependent on a number of factors. Principally among these is an air space of at least 20mm. A still airspace created by a ceiling provides the best results for the foil component particularly for summer conditions where heat flows downward.

Industrial HVAC

-

There is quite a range of Ductliner type insulations, which one should be used?

All Bradford Ductliners will provide good insulation for thermal efficiency and condensation control. The question of which one is related to:

- Sound absorption characteristics: Generally speaking all Ductliners perform excellently in the mid to high frequency range. In the low frequency range absorption increases with thickness and/or density. The final choice will be influenced by the amount of absorption required.

- Compression resistance/smoothness of internal surface: As density of insulation increases so does resistance to "quilting" due to pinning. This has significance in high velocity ducts, where a smooth flat surface is desirable to minimise friction losses, turbulence and air noise. Most commonly Supertel which has a density of 32kg/m3 is used although higher density Ultratel is also popular.

-

Why is Fibermesh 650 recommended generally when blanket insulation is to be used on pipework?

Flexible blanket insulation has much less compression resistance than Rockwool Pipe Insulation. This is partly related to lower density and partly to the flexibility itself. It is important that insulation compresses minimally in service, since compression results in a reduction of performance. Therefore the high density Fibermesh 650 is recommended for pipe insulation where a blanket is preferred. The superb flexibility of the product ensures close contact around pipe circumference and the mesh reinforcement assists stability.

-

What thickness of insulation is needed?

This depends very much on the operating temperature of the system, the desired level of control of heat loss (or gain), maximum surface temperature for personnel protection and the requirements for condensation control. In addition, the reflective properties (surface coefficient) of the insulation cladding also affects heat loss and surface temperature at a given insulation thickness.

-

What type of pipe insulation is best?

The best product for the job will depend on a range of factors outlined below.

Operating temperature for low temperatures down to -40°C Polystyrene pipe insulation is recommended when combined with a suitable vapour barrier. For operating temperatures up to 450°C, either Glasswool or Rockwool SPI (Sectional Pipe Insulation) is recommended. Rockwool is recommended in the upper temperature range because of its greater thermal resistance and compression resistance under operating conditions. For high temperatures up to 650°C Rockwool Pipe Insulation is used.

Cost control for "large" pipes (200mm diameter or greater) Fibermesh 650 may be cost effectively substituted for Rockwool Pipe Insulation, particularly on large projects and where damage via mechanical compression (e.g. personnel climbing over pipework) is a minimal risk. Generally an extra 13mm insulation thickness is required for performance comparable with pipe insulation.

Science of Insulation

-

What are R-values? (Thermal)

Insulation's ability to resist heat flow (prevent heat leaking in or out) is described as its 'R-value'. Incorrect installation, such as compressing or damaging insulation, or leaving gaps between sheets or segments, can result in a product not achieving its specified R-value. This is why it’s important to choose a supplier that you can trust, like Bradford, who has had years of experience and has a reputation of providing quality service.

Bradford has a range of products with various R-Values. Factors like the local climate and available budget should be considered when determining what product best suits your needs. In warmer climates, care should be taken to ensure summer heat does not enter the home and get “trapped” by insulation. Effective shading of windows is highly recommended. Bradford’s Hi Performance range provides the highest available R-Value product in New Zealand – the R7.0.

It’s important that you understand what R-values mean because they can result in you getting the best product for your home. Understanding the R-value for your home is regarded as the best way to compare the different products that are out there in the market.

R-values are the measuring tool we use to rate the level of thermal resistance. Essentially, the higher the R-Value the more effective the insulation is. Bradford has a range of products with various R-Values. Factors like the severity of the weather conditions and available budget should be considered when determining what product best suits your needs.

Material R-values are supplied with bulk insulation (such as Bradford Gold insulation segments) and refer to the insulating value of the product itself. Total R-values are supplied with reflective insulation and depend on the product being installed as specified. R-values can differ depending on the direction of heat flow through the product, more so in reflective insulation rather than bulk.

All new homes being built in New Zealand have certain energy efficiency levels they must meet as required by the building standards. By taking into account R-values of the product will help you comply with what is required in your climate zone.

-

How does heat transfer work? (Thermal)

There are three main types of heat transfer:

1. Radiation

These are rays of heat moving through the air in the same way as we feel the heat from the rays of the sun on our faces. It’s the way your grill works, transferring heat to the food without touching it.

2. Convection

Convection occurs when air molecules themselves heat up and move to another location. In the same way as a convection oven directly heats the air and then blows it around the food, so air can transfer heat in and out of your home.

3. Conduction

Heat is transmitted through the materials of your home, such as the roof and walls. For example, when you place a pot on a stove the inner surface heats the food, because the heat is conducted through the base of the pot.

-

How does insulation stop heat transfer? (Thermal)

Bradford Gold insulation is made up of very thin glass fibres that are matted together to form millions or air pockets. These air pockets are very poor conductors of heat and resist the flow of air or radiation through the insulation.

This ‘resistance’ is known as the R-Value. The higher the R-Value the more effective the insulation is.

-

How is sound transmitted? (Acoustic)

Sound travels easily through the air. When sound waves reach a solid surface they are partially absorbed, but they also cause vibrations that can transmit sound to the other side.

In this way, external noise is easily transmitted through walls and ceilings to the inside of your home. Additionally, noise generated from within your home can be transmitted through internal walls, and even floors, to adjacent rooms.

How insulation helps

Bulk insulation materials such as glasswool and rockwool act like a sponge to help soak up sound energy. When the sound waves encounter the insulation they are partially deflected by the density of the product and partially absorbed due to the millions of interconnecting air pockets.

Insulation products such as reflective foil or foams with hard surfaces are poor noise insulators.

Bradford Acoustic Gold has a similar structure to Bradford Gold insulation, but is much denser. This extra density makes Acoustic Gold particularly efficient at stopping noise, as well as heat transfer within your home.

-

How do I soundproof my home? (Acoustic)

Nothing beats peace and quiet. That's why it is important to consider good acoustic insulation when building a home. Noise has the ability to raise stress, disrupt sleep and generally reduce your quality of life.

These days, there is more external noise – as traffic and housing density increase. Even within our homes, trends such as open plan living, harder surfaces (e.g. timber floors), and more powerful entertainment systems increase noise levels.

Installing acoustic insulation in external walls when you're building your home is the easiest way to effectively reduce unwanted outside noise from heavy traffic, aircraft or noisy neighbours. Also, installing acoustic insulation in interior walls or between first floor ceiling and second storey floor can reduce sound power by up to 75%.

-

How is sound measured? (Acoustic)

Sound pressure is measured in decibels (dB), which is a logarithmic scale. A 10dB increase in sound level is heard as roughly double the loudness of the original sound by the ear. Sound levels between 35dB – 45dB are generally considered comfortable.

The acoustic performance of a wall or floor system is measured by the Weighted Sound Reduction Index (Rw). It is a single number acoustic rating that takes into account the sound reduction of the system at a number of different frequencies and is used to easily compare different types of construction. The higher the Rw the better the acoustic performance of the system.

Quickly download brochures, datasheets, installation guides, technical design guides and more.

Everybody wants a comfortable home. We have information, tips and resources available for you to understand how to make your house a comfortable, energy efficient and healthy environment for yourself and your family.